Ah, the joys of cruising: Sun-soaked days on the deck, endless buffets, Broadway-style shows, and… propulsion issues? That’s right; if you’ve been following the drama surrounding Carnival’s Vista-class ships—namely, the Carnival Vista, Carnival Horizon, and Carnival Panorama—you may have noticed a troubling trend. These ships, designed to offer all the glitz and glamor of a modern cruise, have been struggling with some propulsion problems. But what does this really mean for you, the eager cruiser? Let’s break it down in a way that even someone who’s never stepped foot on a ship can understand.

More Trouble for Carnival Vista: Cruise Cancelled Amid Ongoing Propulsion Issues

Azipods: The Magic Behind Modern Cruising

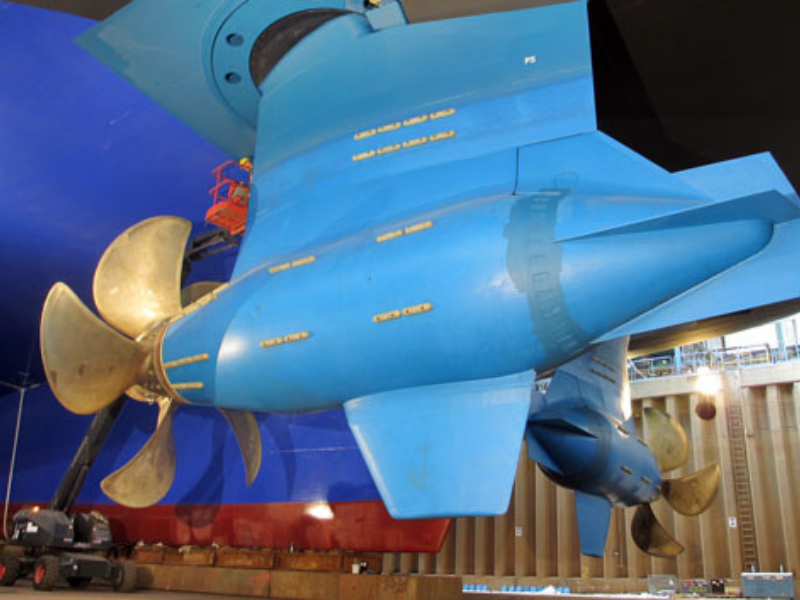

Before we dive into the nitty-gritty of what’s going wrong, let’s talk about what azipods are. Imagine this: You’re on a ship, gliding effortlessly across the ocean. You see no large rudder swinging back and forth to steer, nor do you hear the loud hum of traditional propeller shafts. The secret behind this smooth, almost serene movement? Azipods.

Azipods are essentially a type of marine propulsion unit. They’re these high-tech pods attached beneath the ship, housing an electric motor that directly drives a large propeller. What makes them unique is their ability to rotate 360 degrees, providing both propulsion and steering. This is a big step up from the old-school rudder and propeller combo.

Why Do Ships Use Azipods?

Ships, particularly cruise liners like those in Carnival’s Vista class, use azipods because of their enhanced maneuverability and fuel efficiency. They can easily navigate tight spaces, like busy ports or narrow straits, without the need for tugboats. With azipods, a ship can pivot on a dime—well, not literally, but you get the idea. It makes docking and undocking a breeze, which is especially handy as ships get bigger and bigger.

Plus, azipods are quieter and lead to less vibration, making for a more comfortable experience for passengers sipping cocktails on the Lido Deck.

The Maintenance Game: What Do Azipods Need?

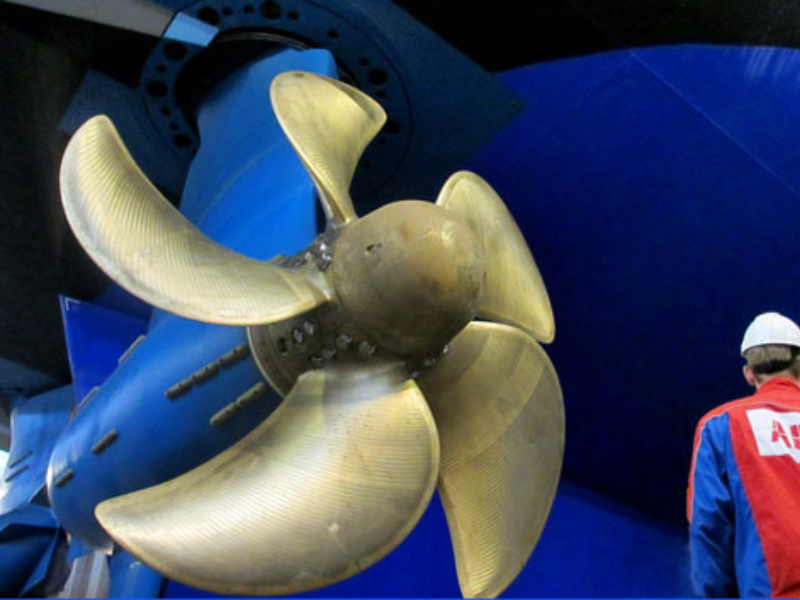

Like any piece of sophisticated machinery, azipods require regular maintenance to keep them in top shape. We’re talking about everything from routine inspections to more extensive check-ups that might require dry-docking the ship. Maintenance usually involves checking for wear and tear on the bearings, ensuring the seals are intact, and making sure the electric motors are functioning optimally.

Generally, ships undergo regular maintenance checks during scheduled dry-docks, which happen approximately every five years. It’s during these dry-docks that major overhauls can be done, like replacing worn-out parts, upgrading software that controls the azipods, and reapplying special coatings to reduce drag in the water.

How Long Do Azipods Last?

Now, let’s chat about longevity. Azipods are like the tires of a car—you don’t necessarily need to replace them frequently, but they aren’t going to last forever either. The expected service life of an azipod system is usually around 15 to 20 years, depending on how heavily they are used and how well they’re maintained. But that’s just the average; some azipods might need more attention much earlier.

Carnival’s Vista-class ships, launched between 2016 and 2019, should be in their prime. So why are we already seeing so many problems?

The Trouble with Vista-Class Azipods

And here’s where it gets interesting. For some reason, the azipods on Carnival’s Vista-class ships are acting like that one smartphone that needs constant charging and freezes every time you try to scroll. What gives?

It turns out that the azipod units on these ships, produced by a company called ABB, are facing recurring technical problems. The issues seem to revolve around the bearings in the azipods. If the bearings aren’t working right, the whole pod can’t rotate as it should, affecting both propulsion and steering.

For a ship, it means slower speeds, longer trips, and, in some cases, skipped ports or altered itineraries.

The recent issues with Carnival’s Vista-class ships’ propulsion systems bring to mind a similar situation faced by another major cruise line—Norwegian Cruise Line (NCL). In a case that has caught the attention of the maritime industry, Norwegian won a lawsuit against ABB, the manufacturer of the azipod units, for $159 million in damages. The case revolved around defects and misleading information about the azipod systems installed on NCL’s ships, highlighting broader concerns that could potentially be relevant to Carnival’s current predicament.

The lawsuit between Norwegian Cruise Line and ABB, the company that manufactures azipod systems, stemmed from recurring issues similar to those we see with Carnival’s Vista-class ships. Norwegian argued that the azipod units, which were marketed as reliable and efficient, instead suffered from repeated mechanical failures that severely impacted the cruise line’s operations. These failures led to delays, costly repairs, and in some cases, cancellations—much like what Carnival is experiencing now.

The crux of the case was that ABB allegedly provided inaccurate or incomplete information regarding the reliability and durability of their azipod systems. After a lengthy legal battle, a jury awarded Norwegian $159 million in damages, concluding that ABB was liable for misleading the cruise line about the performance and dependability of the azipods.

Carnival Corporation and ABB Team Up for Maintenance

In October 2023, Carnival Corporation and ABB entered into a strategic partnership aimed at enhancing the maintenance and service of azipod propulsion units across Carnival’s global fleet – including the Vista-class vessels. Under the partnership, ABB will provide regular maintenance, performance optimization, and round-the-clock remote diagnostics.

This collaboration represents a proactive approach to addressing the recurring azipod issues that have troubled some of Carnival’s ships. By working closely with ABB, Carnival obviously is trying to reduce unscheduled repairs and operational disruptions, but sometimes even the best planning doesn’t work out.

How Do You Fix Azipod Problems?

Repairing azipod issues isn’t like taking your car to a quick oil-change shop. It’s a bit more complicated, and there are a few different options available depending on the severity of the issue:

- Underwater Repairs: For minor fixes, some repairs can actually be carried out underwater using divers or remotely operated vehicles (ROVs). This is a less costly option and doesn’t require taking the ship out of service. However, this approach is limited to simpler issues like replacing seals or inspecting for damage.

- In-Port Repairs: Sometimes, a ship can pull into a port where specialized teams are flown in to perform repairs without needing to go to a dry dock. This could involve things like replacing worn-out bearings or fixing alignment issues. The ship may need to stay in port a bit longer than planned, and passengers might find themselves with an extra day to explore—a win-win if you’re in a great location!

- Dry Dock Overhaul: When more extensive repairs are needed, dry docking is usually the only option. This involves taking the ship out of the water completely, which allows for a full inspection and any necessary major repairs or replacements. However, dry docking is costly and can take weeks or even months, affecting cruise schedules and potentially leading to canceled sailings (like what recently happened with Carnival Vista).

- Complete Azipod Replacement: In rare cases, when the azipod is beyond repair, the only option is a full replacement. This is a massive undertaking, both logistically and financially. It requires not just a dry dock but also waiting for the new unit to be manufactured, delivered, and installed. It’s the ultimate “nuclear option,” so to speak.

The Cost of Repairing Azipods

Now, let’s talk about the dollars and cents. Repairing or replacing an azipod isn’t cheap. Minor underwater repairs might cost in the low hundreds of thousands, but dry-dock repairs or replacements can easily run into the millions. Each day a ship spends out of service is also a day of lost revenue, not to mention compensation for passengers on canceled cruises.

For instance, when Carnival Vista had to undergo repairs in 2019, the company reportedly had to charter a semi-submersible vessel, BOKA Vanguard, to lift the ship out of the water for repairs. The total cost? Well, let’s just say it was a bit more than what you’d find in the ship’s casino vault.

Why Do These Issues Keep Happening?

You might be asking yourself: if azipods are so high-tech and efficient, why do they keep causing problems for the Vista-class ships? Good question. Some industry experts speculate that the issues might stem from the unique demands placed on the azipods by these ships’ sizes and itineraries. Remember, the Vista-class ships are some of the largest in Carnival’s fleet, and they’re constantly on the move, with minimal downtime.

There’s also the possibility of manufacturing flaws or design limitations that weren’t apparent when the ships first set sail. When you’re dealing with such complex engineering, sometimes things don’t show up in testing or early use but reveal themselves over time.

For those of you planning to cruise on one of these ships, don’t let this scare you off. Azipod issues, while inconvenient, are relatively rare in the grand scheme of things. And let’s face it: the lure of endless buffets, beach excursions, and lounging by the pool with a fruity cocktail is hard to resist.